Formerly known as Technocore Engineering Services ( 1997 - 2020 ), now known as YHPC CONNECT .

Serving the Wire Harness Industry since 1997

YHPC Connect

Incorprated in Singapore, company registration no.: 53437885D

Contact Name &No.:

PC Lee 65-91293768

E-mail:

yhpc99@gmail.com

WeChat: PCLEEJUL1962

WhatsApp : Lee Peng Chai LINE : YHPC-PCLee

MAKING WAVES IN THE INDUSTRY. WITH OUR POWER SAVING MODULES.

POWER CORD / CABLES

Our team of expert design engineers works with customer supplied requirements or specifications to design cables that perform in the most demanding applications—microminiaturization, high flex life, autoclavable, low noise, low-elongation, high tensile strength, ultra-flexibility or hybrid cables. We maintain a large raw materials inventory including including many conductor materials, plastics and other raw materials required for medical device cables.

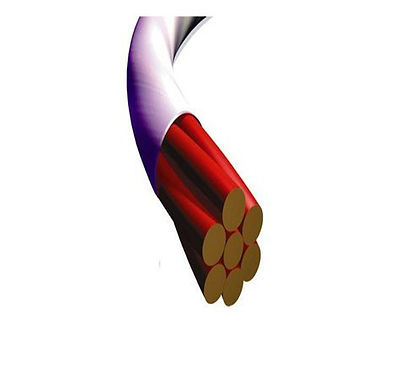

LITZ WIRE

"Litz" comes from the German "Litzendraht", refers to a conductor is insulated by a plurality of separate conductors twisted orbraided. Typical applications include: high-frequency inductors, transformers, converters, fuel cells, motors, communications and IT equipment, ultrasonic equipment, sonar equipment, televisions, radio equipment, induction heating, and so on.

APPLICATIONS

-

Magnetic levitation systems for trains.

-

Catapult launch systems for aircraft carriers

-

Special induction heating

-

High-frequency inverter power

-

Transformers

-

Fuel Cells

-

Motor

-

communications and IT equipment

-

Ultrasonic equipment sonar equipment

-

TV

-

Radio equipment and so on

SPECIFICATIONS

-

#1: UL 60950 & IEC 60950 have maximum temperature rating of 180C degree, Class H.

-

#2: PFA 0.0015" wire for UL60950 approval is pending. Approval range: (1)single layer 22AWG---40AWG. (2) Double and triple layers: 18AWG--40AWG

-

#3: IEC 60601 approval (pending) range: ETFE/FEP/PFA; 3 layers; min. 0.002” per layer.

-

#4: Double and triple insulated wires approved for use in UL NE-F1 Insulation System (except 0.0015” PFA).

-

#5: We use DuPont ETFE / FEP / PFA.

Special Application Note

-

RoHS lead free soldering

-

NEWind® 0.0015” PFA wire is an excellent option for use in a lead free soldering process. Customers of Polyester resin based wire or certain ETFE wire having any lead content soldering issue due to RoHS requirements should talk to us for RoHS wire solution.

-

Specifications are subject to change without notice, and exceptions may apply depending on application, wire and other variables. Optional equipment may require standard machine modification and/or later specifications.

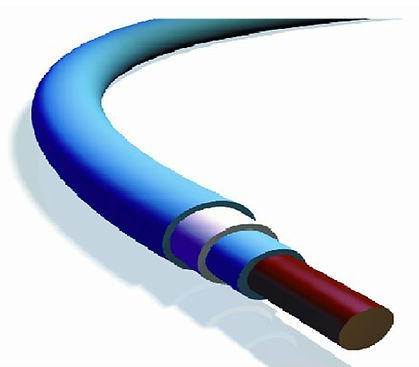

TRIPLE-INSULATED WIRE

Triple Insulated Wire is a high performance insulated wire, this wire has three insulating layers, the middle core, the first layer is a polyamine golden film having a thickness of several micrometers, but can withstand pulses 3KV pressure, the second layer of paint is high insulating coating, and the third layer is a transparent layer of glass fibers, the total thickness of the insulating layer is only 20-100um, the advantage of high dielectric strength can be between any two exposed 3000V AC safety voltage and current density.different insulation materials for different occasions such as insulating layer is resistant Teflon ETFE, because high temperature and high insulation, and widely used in high-frequency transformers, computer power supply, cell phone chargers; PFA & ETFE insulation layer, the application in communications, transformers insulated wire and magnetic components.

FEATURES

-

1, the coil is easy to roll;

-

2, high voltage insulation, can save insulating tape, insulating spacers;

-

3, superior wear resistance of high-speed automatic reel offers possible;

-

4, triple insulation, no pinhole phenomenon;

-

5, can be stripped without soldered directly.